Faccin designs, manufactures and supplies machines for dished ends able to assure high productivity and maximum reliability in forming sheet steel, stainless steel and aluminium to produce tanks for tanker trucks.

The forming process

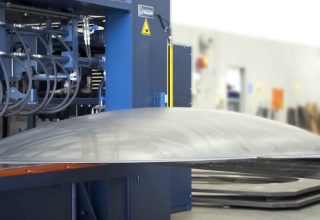

PPH series water presses by Faccin are widely used in the sector because they enable hydroforming of polycentric, oval and circular dished heads with thickness up to 8 mm. This forming process is done by pressing the plate against a die shaped according to the desired dished head shape to be obtained with high pressure water. A progressive increase in water pressure allows for achieving the required yielding of the material to obtain dished head crowning within few minutes. The PPH is equipped with sensors that automatically stop the forming cycle when the desired depth of the dished end is reached.

The PPH machine

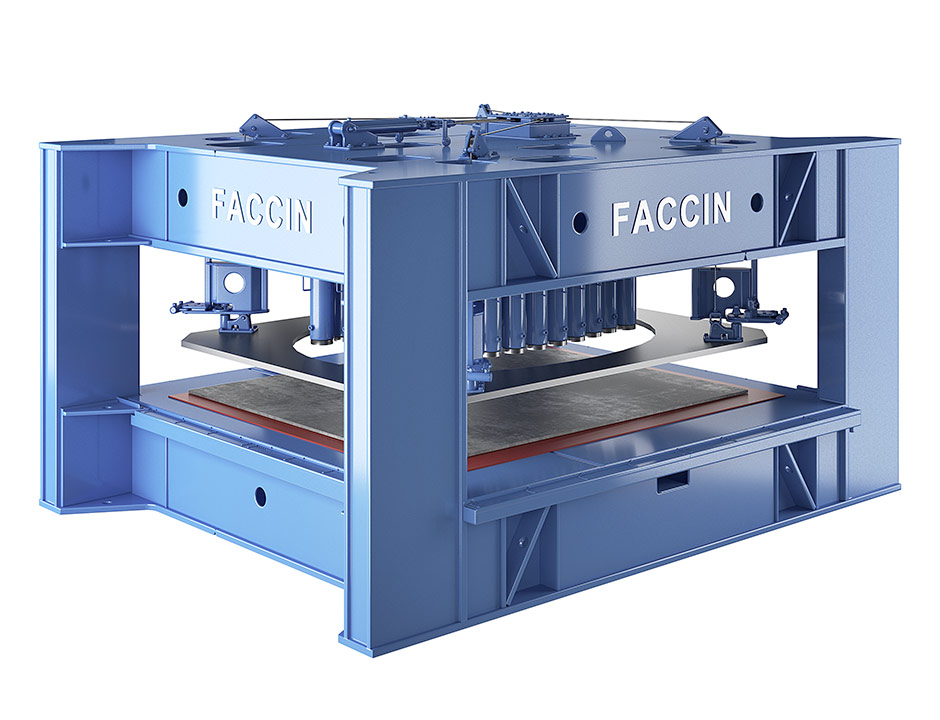

The PPH water press machines are built in-house, like all the Faccin machines, with an oversized frame made by two heavy duty top and bottom frames and four heavy tie-rods. Top brand European components are used for the hydraulic and electrical unit. Faccin’s PPH hydroforming presses feature a set of hydraulic cylinders that keep the plate pressing system anchored to the bottom, creating a total force of over 2,500 tonnes. In addition, water presses have a special sealing system that ensures a seal against liquid seepage and leakage. The machinery in the PPH series designed and assembled by Faccin are CNC water presses able to ensure complete automation of the production process. Furthermore, the water presses are equipped with optional loading/unloading systems for significant reduction of production times.

Hydroforming press: a smart solution for series production of dished ends

The production of dished ends through water forming is ideal for producing dished ends with particular surfaces, like mirrored surfaces that would otherwise be damaged by the normal forming process through regular presses. The PPH hydroforming press for dished ends is preferred by manufacturers of fuel tanks that are producing polycentric dished ends in series.