Find the appropriate machinery for your production needs »

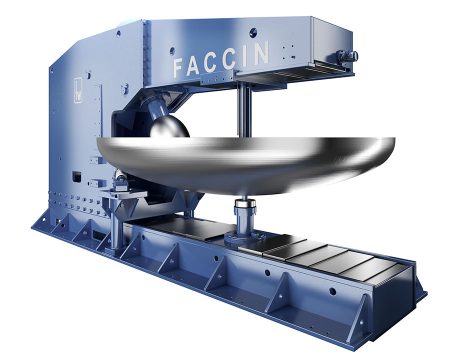

DISHED HEADS

Manufacturers of dished heads for tanks and pressure vessels require machines able to ensure high performance and high productivity. Faccin offers dished head production lines that include technologically advanced dishing presses with an automatic manipulator, flanging machines and manipulators, designed to offer maximum reliability and to meet the needs of manufacturers of dished heads in terms of achieving tolerances and lamination reduction.

The first step for making dished ends is to cut the plate to obtain the circular blank; an operation normally done with a circular shear for thicknesses below 10mm or with normal cutting tables when thicknesses are above 10mm.

The second step is the dishing process with the PPM dishing press that is equipped with the specific dies, which can form the crowning radius with multiple hits. The pressing is a repetitive process run in automatic mode by the CNC that control the press and the manipulator that handles the dished ends and distributes the hits.

When the plate is dished with the correct crowning radius, the dished head is completed by forming the edge through the flanging machine. The flanging machine is, in fact, forming the knuckle radius by spinning the material. This process can also be controlled by CNC in case of series production. In order to complete the dished ends, Faccin Flanging Machines can be equipped with a special machining tool used to adjust the depth of the dished end and to place the chamfer for the circular welding.