Global gas demand is back on track?

After a 4% drop in 2020, gas demand is expected to grow by 0.9 percent from 2020 to 2035 and will be strongest-growing fossil fuel with a moderate decline only after 2035.

Among all the regions, North America and Middle East are projected to contribute with half of the net increase in supply. On the other hand, the consumption of natural gas is expected to have the fastest growth, particularly in the Asia-Pacific region due to the lower cost compared to other fuels, the use of natural gas as raw material in fertilizers production, environmental benefits and energy security, with the consequent growth of the natural gas pipeline.

Pipeline and energy infrastructure companies face huge operational challenges for the transportation of crude oil and natural gas in either a liquid or gas form, from the production points to refineries and distribution centres. Pipes production is an area of such difficulty that only companies with many years of experience and high technology background can be trusted to reliably design and provide pipes-manufacturing machines suitable for the most challenging projects.

Faccin has been a reference point throughout the years for its expertise in designing and manufacturing special machines for the production of pipes.

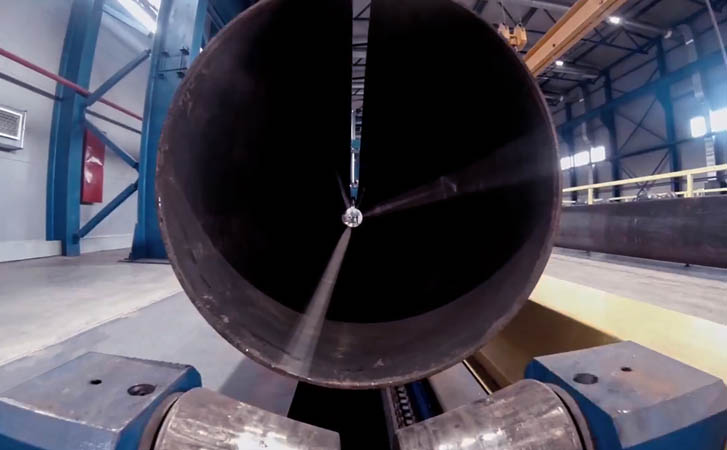

Recently the company has completed a sturdy electro-welded 3-roll plate rolling machine that includes exclusive features such as variable axis configuration, maximum pipe length of 12.000 mm/40 feet, anti-deflection system for top roll, anti-deflection system for bottom rolls, 3 rolls drive and automatic pipe ejection system and others.

This CNC-controlled high-performance pipe mill bending roll is able to support the production of pipes delivering productivity, repeatability and automation of the entire manufacturing process and is able to reach specific technical and roundness tolerances while offering a high-quality finished product that meets the high API standards.

|

|

To further increase the production speed and automation an accurate post-bending machine that prepares the pipe for welding can be added as well as a series of outboard motorized guide rollers that control the movement of the pipe from the plate rolling machine to the post-bending machine and successive working stations achieving a fully automated manufacturing process.

This giant is ready to find its new home.

_______________

Should you be interested in this technology, do not hesitate to contact us