Faccin has always been one step ahead in plate rolling development and it has in its DNA the continuous research of new techniques to satisfy the customer’s challenging needs.

Faccin has always been one step ahead in plate rolling development and it has in its DNA the continuous research of new techniques to satisfy the customer’s challenging needs.

When a customer specialized in series production of rolled parts for the Automotive Industry came to Faccin with the need of a special solution to produce thousands of thin and narrow parts per day, difficult to handle and roll, with maximum repeatability and minimum workmanship costs, the Faccin engineers proposed a tailor-made solution.

For the rolling machine, the key was to use the renowned HCU machine, 2 rolls Fast Plate Roll that thanks to its urethane roll can roll parts with total pre-bending in one pass and with no flat.

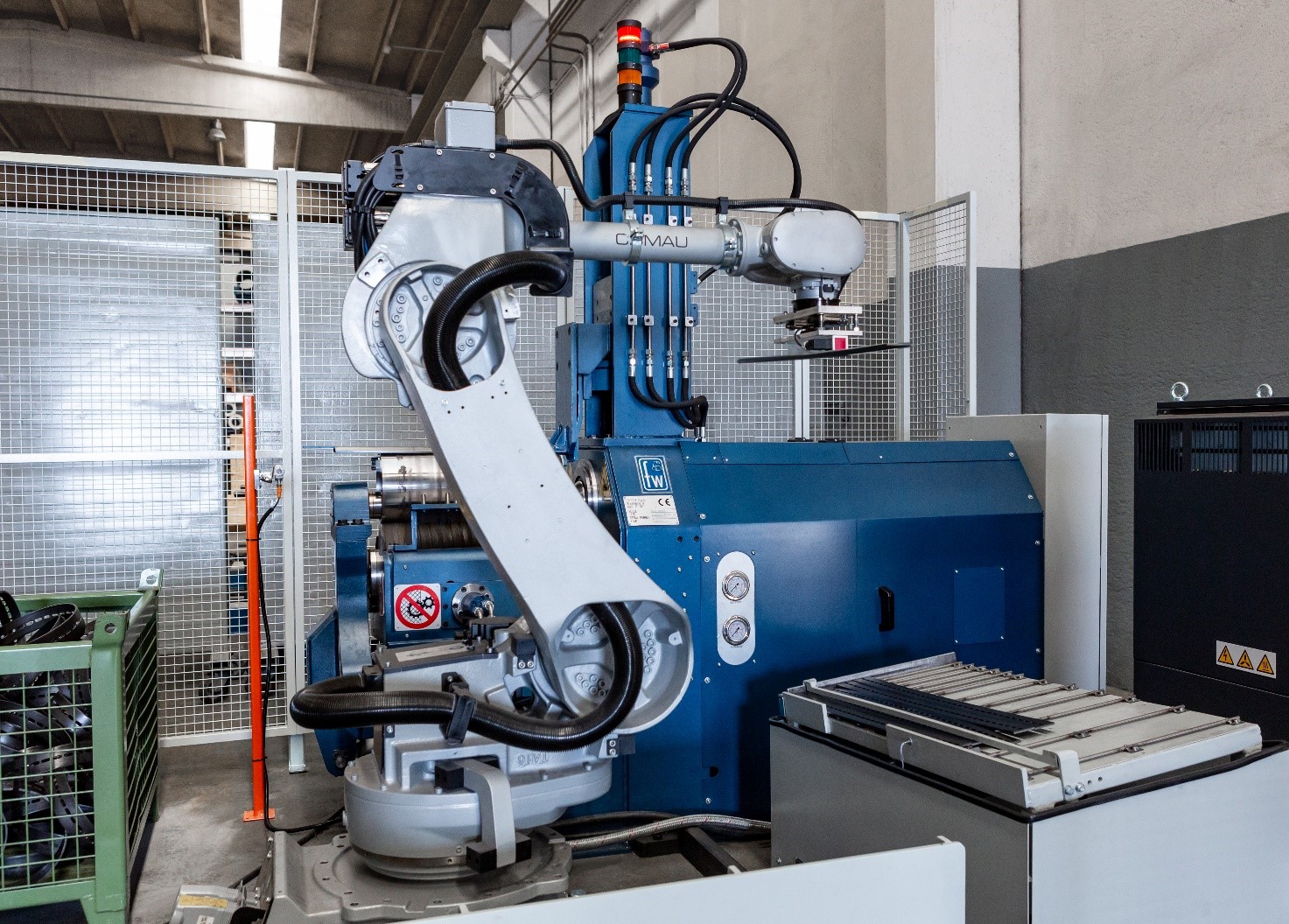

For the handling, the Faccin engineers decided to combine the HCU Fast Plate Roll with a Hi-tech 6 axes anthropomorphic Robot, a solution appreciated by the customer for its versatility and automation.

The integration was not a problem thanks to the latest electronic technology on board of the HCU machines and the result has been greater than expected: high productivity, no operator needed, and the highest production quality testified by an extremely high OEE percentage on a machine working 24/7.